From the Factory Floor to the City Sidewalk: A Review of Automate 2022

This article was originally published on Materials Handling Network.

I recently attended Automate 2022 in Detroit, a premier automation event that spans a powerful showcase of automation solutions from the factory floor to the city sidewalk. A wide range of automation topics was discussed, from the role of robots in the manufacturing process to which AMR to invest in for your material handling to how robots will manage themselves while delivering consumers their takeout dinners. This was a very mature and savvy robotics audience. What was particularly eye-opening for me was that in the context of nascent and emerging technologies, there is a lively debate as to what types of automation are the best fit for specific use cases, especially in the warehouse and fulfillment space. Here are some of my observations from the show.

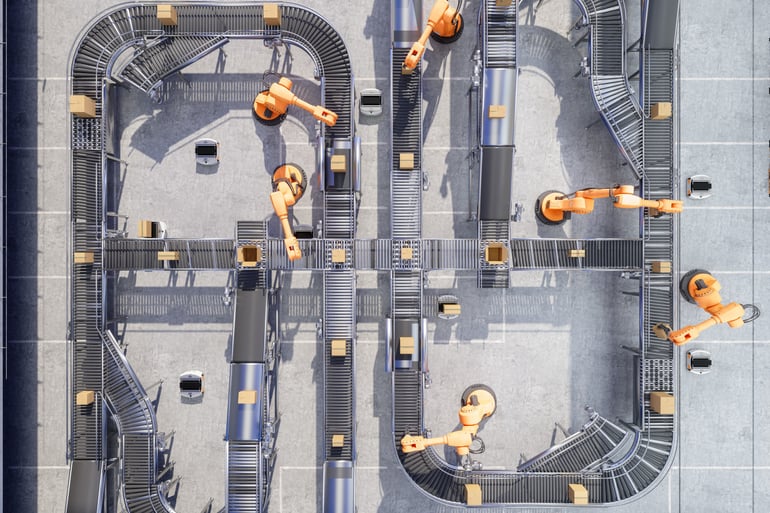

The factory floor still dominates.

No surprise, but automation and robots for the factory floor are in a much more mature state than in other aspects of the supply chain. Vendors like Fanuc were proudly displaying a robotic arm capable of deftly picking up and moving a Corvette around as a seasoned waiter would navigate a busy dining room with a full tray of dishes at the London Chop House. The adoption and advancements of robotics arms for the manufacturing sector are well-established within the industry. Look for these learnings and advancements to continue to expand into other parts of the supply chain, especially when it comes to material handling within the warehouse. The potential to combine AMR (autonomous mobile robots) with the robotic arms being used in the factory is the next frontier. Look for the two worlds of robotics to continue to converge toward a combined solution.

On the scale of maturity, the warehouse lags behind the factory floor when it comes to automation and robotics.

One aspect was clear during my time in Detroit: There remains a learning curve when it comes to the options and types of automation that are available for those in warehouse management. What struck me was the need to educate about the different types and flavors of automation that are available for warehouse fulfillment. From AGV to AMR, GTP to GTR — the list (of acronyms) goes on. What this indicates is that the market remains in its early days. The interest, need and general curiosity remain high, but the understanding remains relatively low. Nonetheless, there is an appetite to understand this world better because to quote Lou Finazzo from Fanuc, it is no longer “am I going to,” but “I have to,” when it comes to the adoption of automation.

One recurring topic throughout the event is the need for interoperability between platforms. While we might not know exactly what type of systems we need, it was evident that as attendees moved toward more automation, those automated ecosystems will almost always be a combination of technologies within a fulfillment operation. That mix of solutions will require interoperability and communication between different robots. To that end, the nonprofit firm Mass Robotics is working with industry leaders to establish standards for communications. Knowing where each robot is, what task they are undertaking, and other basic data is a vital first step. How interoperability matures will be important for the industry as a whole; in all likelihood, there will be a push to have a more centralized command and control platform, allowing warehouse operators to have one command center. This will provide an optimized and harmonized control of all the robotic, and potentially human, assets on the warehouse floor. This need remains vital for the future state of fulfillment and the warehouse, but what that solution will resemble remains a work in progress. I would not expect to have a clear answer any time soon. That said, any warehouse operator looking to bring more robots into their operations must work with their partners to have more clarity on where this is heading and how to prepare.

Finally, the closer the automation gets to the consumer, the less mature the solutions are.

Drone delivery of your prescriptions, your groceries being delivered by an autonomous vehicle, or your most recent e-commerce order being dropped off by a robot all remain somewhere on the horizon. There is no shortage of investment and interest; for example, the sidewalk delivery market has over 30 new robot vendors looking to offer solutions. While this may not come as a surprise, it’s worth noting that moving robots into the “wild” to interact seamlessly amongst the public will take longer. Offset this with robots on the manufacturing floor or the warehouse, where they are in a controlled environment amongst trained personnel. A robot sharing the sidewalk or the grocery store aisle with the public will need greater scrutiny, standards, rules, and comfort levels before it becomes more prevalent. Look for more standards such as ISO 4448-5 on how to operate outdoor AMRs, as well as more robots to make their way into our daily lives. Providers like Braincorp and Avidbot are bringing cleaning and scanning robots to the grocery store — in public, but within the controlled space of the grocery store. Whether we start seeing more cleaning robots, security robots, and even room service delivery robots, as the public becomes more comfortable with robots, we will see a growing number of use cases and applications.

Robots have become a need to have, not a nice to have. The pulse of Automate 2022 pointed toward some exciting growth within the warehouse and material handling space, continued and steady adoption on the manufacturing floor, and potentially some innovative solutions that touch the end customer. Keep an eye on this space, the rise of robots, the need for interoperability, and the digital layer that is vital to manage and optimize this technology.